Quality Control

Quality Control

Our commitment to quality is paramount. As a result we’ve invested greatly in effective quality management and monitoring processes that can be relied upon when machining high-quality products. Most recently we have enhanced our Metrology Laboratory to embrace theoretical measurements and determinations at any level in any field of science and technology.

At the heart of our quality regime is our proprietary Statistical Process Control (SPC) system. Every part of our production process is recorded on SPC allowing complex computer models to monitor and maintain high production standards, which ensures a constant high quality across every finished product.

Samples are analysed at all stages of production and the results are kept on computer record for a period of seven years. This ensures full traceability on every extruded, moulded or skived product or machined component – from raw material to the finished article.

This quality system was first approved by the Aeronautical Inspectorate Directorate (AID) in 1956.

Today Dalau operates a ‘TQM’ Total Quality Management system that forms the basis of day-to-day processes. We meet the exacting standards of:

- ISO 13485:2015 Medical Devices – Quality Management System

- AS 9100:2018 Aerospace Quality Management System

- ISO 9001:2015 Quality Management System

- ISO 14001:2015 Environmental Management System

- ISO 45001:2018 Occupational Health & Safety Management System

- WRAS Approval Water Regulatory Advisory Scheme

- Disability Confident Certificate Disability Confident Scheme – UK Government

- UL – Yellow Card UL Lab

Control and support facilities

Specific facilities include ‘in-house’ blending technology and the introduction of a clean climate-controlled production facility. A clean room system particularly for use in high specifications applications (aerospace and pharmaceutical etc.), is available.

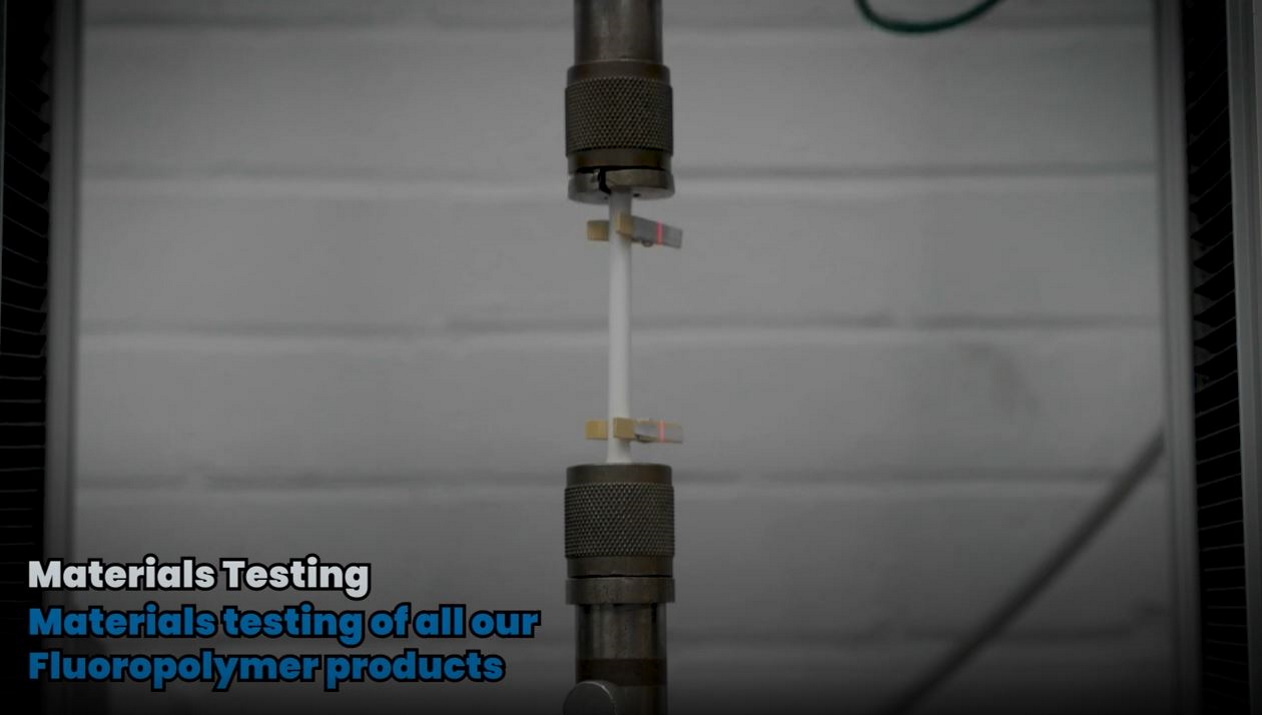

Precision product testing and control

As well as standard batch testing for quality, including tensile, stress and compression testing, we also subject all semi-finished products to our unique Differential Scanning Calorimeter (DSC) testing. This ‘thermal fingerprinting’ provides important information about the material’s thermal behaviour and checks that the material has been fully sintered. Through its exact calibration DSC enables the recording of melting temperatures and molecular weight.

Complex temperature programs for all product samples provide effective data to quality control, minimising operational inconsistencies. This results in higher integrity products for our customers.

Our non-contact measurement systems measure every feature faster than conventional methods, eliminating human error and providing accurate, repeatable data collection whilst improving flexibility in your measurement processes.

Dalau competes on the highest level and our reputation depends on the quality of the measurements made. The video measurement technology of the OGP SmartScope CNC 250 can improve measurement through output and accuracy.

CMM

Our state-of-the-Art Coordinated measuring machines (CMM) are ideal for accurately checking some of the very small features produced on our sliding head machines, and CNC milling centres and our team had specialist training to ensure we achieve the best results possible.

Play

Play